Our company was established since 1995 by Gondal brothers

Precast Hollow Blocks

Precast Hollow Blocks

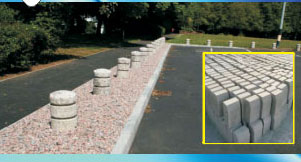

Precast Concrete Pavers

Precast Concrete Pavers

Precast Concrete Parabolic Segment

Precast Concrete Parabolic Segment

Precast Concrete Slab

Precast Concrete Slab

Precast Concrete Road Kerb

Precast Concrete Road Kerb

Reinforced Concrete Pipe

Reinforced Concrete Pipe

Precast Concrete Wall

Precast Concrete Wall

Precast Concrete Hollow Plank

Precast Concrete Hollow Plank

Precast Concrete Girder's

Precast Concrete Girder's

Precast Concrete Garden Path

Precast Concrete Garden Path

Precast Concrete I Pole

- Precast Concrete I Pole

Precast Concrete Y Pole

Precast Concrete Y Pole

Precast Concrete Nakka

Precast Concrete Nakka

Precast Concrete I Beam

Precast Concrete I Beam

PCC is Plain Cement Concrete. There is no reinforcement in it. Suitable to take only compressive loads. RCC is Reinforced Cement Concrete in which the structure is reinforced with steel. The steel takes tension and the concrete the compression. There is one more type called PSC , Prestressed Concrete in which steel inside is pre stressed in the opposite direction so that it can take more load

Precast is one of the construction methods that use the principles of industrialization in the construction process

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and lifted into place. In contrast, standard concrete is poured into site-specific forms and cured on site.

Precast stone is distinguished from precast concrete by using a fine aggregate in the mixture, so the final product approaches the appearance of naturally occurring rock or stone. By producing precast concrete in a controlled environment (typically referred to as a precast plant), the precast concrete is afforded the opportunity to properly cure and be closely monitored by plant employees. Utilizing a Precast Concrete system offers many potential advantages over site casting of concrete. The production process for Precast Concrete is performed on ground level, which helps with safety throughout a project. There is a greater control of the quality of materials and workmanship in a precast plant rather than on a construction site. Financially, the forms used in a precast plant may be reused hundreds to thousands of times before they have to be replaced, which allow cost of formwork per unit to be lower than for site-cast production .

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form, by injected humour, or randomised words which don't look even slightly believable. If you are going to use a passage of Lorem Ipsum

Copyright @ Gondal Concrete. Designed By TheWebTask